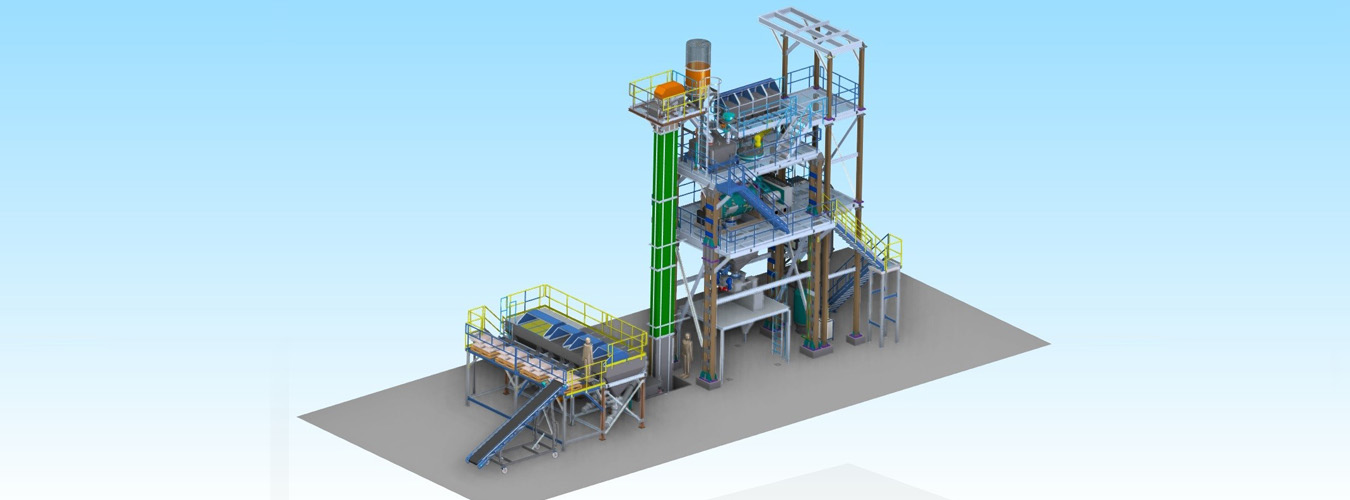

Thermoplastic Road Marking Paint Manufacturing plant

Briefing

The Indian road marking paint industry, serving as the backbone for traffic management and safety, is witnessing substantial growth, driven by the country’s sprawling road network expansion and urbanization. This niche yet critical sector, which provides essential markings for lanes, pedestrian zones, and traffic directives, is buoyed by government-led infrastructure initiatives such as the Bharatmala Pariyojana and the Smart Cities Mission. These projects underscore the need for high-quality road markings to ensure safety and efficiency in transportation. As India continues to develop its highways and urban and rural roads, the demand for advanced, durable, and eco-friendly road marking solutions is escalating. Enhanced safety regulations and a growing awareness of the importance of road safety are further propelling the industry towards innovative products, including thermoplastic materials and reflective coatings. This evolution reflects a commitment to keeping pace with infrastructure growth and adopting sustainable practices within the road marking paint industry.

RMX’s launch of a manufacturing plant for making road marking paint products marks a strategic move to cater to the increasing demand in the Indian market. This initiative positions RMX as an innovator in road safety and underscores its commitment to producing advanced, eco-friendly road marking solutions.

Benefits & features :

- Fully Automatic PLC Based design

- Compact Design of plant

- High Accuracy Mixer With Liquid Injection System

- Handling 10-12 various types of Raw materials with precise weighment (+/- 0.5 % Accuracy Factor)

- Handling of Low Density(0.3) to High Density(1.5) Raw Materials

- IOT Facility

- Maximum Packing Accuracy

- Plant capacity range of 5 to 20 TPH

- Plant Min. Operational Area: 3000 to 8000 Sq.ft