RMX LCCP

Briefing

Concrete, the most widely used human-made material, is fundamental to construction worldwide. The demand for high-quality construction materials is ever-increasing, driven by sophisticated building structures and the need for enhanced concrete properties. Construction chemicals have emerged as a pivotal solution, offering improvements in strength, durability, and waterproofing. RMX leverages significant domain experience to provide comprehensive solutions in advanced liquid construction chemical plants, catering to the growing global demand influenced by rapid urbanization and advanced construction activities.

Why Choose RMX?

- Expertise in Material Management: Unloading, storage, dosing, weighing, mixing, packing, and related services.

- Versatile Plant Solutions: Horizontal and vertical options, with manual to fully automatic systems. Capacities from 5,000 to 70,000 tons annually.

- Complete Project Lifecycle Support: From engineering design to after-sales support, including equipment supply, erection, commissioning, training, and handover.

- Customized Solutions: Tailored to match specific project requirements—plot size, production capacity, product range, and expandability.

- Dedication to Success: A commitment to innovation, operational excellence, and client partnership.

Products We offer

The agitator vessel is a crucial component for mixing liquids, solids, and facilitating chemical reactions, ensuring uniform and homogeneous content essential for high-quality construction chemical manufacturing.

Technical Specifications:

– Material of Construction: SS 304 / SS 316, with PTFE lining options.

– Capacity: 500 Liters to 15,000 Liters.

– Agitator Design: Single or Twin shaft configurations for diverse mixing needs.

– Features: Multiple nozzle types for comprehensive process control, VFD for speed adjustment.

– Quality Assurance: Undergoes joint efficiency testing, radiography, and Hydrotest

Storage tanks are integral for storing the raw materials used in construction chemicals, designed for efficiency and safety.

Technical Specifications:

– Design: Vertical or horizontal models with conical or spherical tops and bottoms.

– Material Options: SS 304, PP + FRP; mild steel for non-contact parts.

– Accessories: Includes ladders, top railing, and various nozzle types for operational flexibility.

– Safety Inspections: Subjected to rigorous testing, including joint efficiency, radiography, and Hydrotest

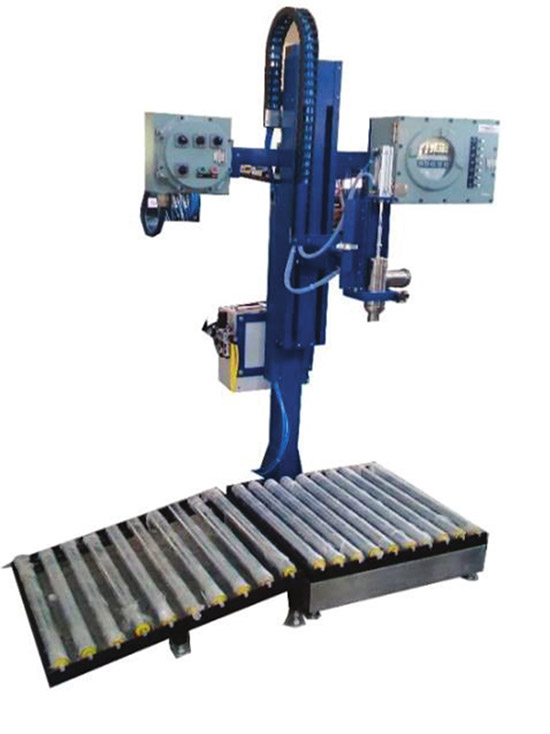

A versatile and precise filling and packing system is essential for handling various types of liquids and ensuring accurate packaging of construction chemicals.

Technical Specifications:

– Accuracy: ±0.05% relative to system capacity.

– Modes: Automatic and manual operation modes.

– Container Compatibility: Accommodates a wide range of container types with easy adjustments.

– Features: Advanced weighmetric filling with 3-speed control, power failure resume function.

– Construction: MS painted structure with SS 304 wetted parts and Teflon seats.

Key Features

1) Capable to store different recipes,

2) 3-speed filling for greater accuracy and higher speed

3) Resumption of filling from the same point in case of power failure,

4) Height adjustment for filling different heights of containers on the same system

5) Normal Weighing / Filling Accuracy is ±0.05% of system capacity

6) Operation in auto/manual mode.

Comprehensive Plant Integration Solutions by RMX :

Beyond the foundational components, RMX extends its offerings to encompass every essential element needed for the complete plant realization. We pride ourselves on delivering a seamless integration of the plant, meticulously selecting pumps, valves, weighing, and batching systems, and an array of sensors to meet the precise requirements of each project. Our solution’s heart lies in a state-of-the-art, fully automatic control system powered by advanced PLC and SCADA technologies. This system is tailored specifically to align with the unique needs of your product and process, ensuring an unparalleled level of operational efficiency and control.

Leveraging our deep industry expertise and technological capabilities, RMX guarantees the supply of critical components and a comprehensive, customized integration service. Our approach is designed to provide a turnkey solution that encapsulates all aspects of plant operation, from material handling to final product output, all configured to meet the exacting standards of your production goals and quality requirements.

Choose RMX for an end-to-end solution that combines advanced technology, expert integration, and unwavering support, ensuring your plant operates at the pinnacle of productivity and innovation.