A - Z

From A to Z, RMX Delivers: Your Product Hub

The pneumatic screw pump, offered by RMX, is an industrial-grade material injection device engineered for introducing dry, pulverized substances into a pneumatic transport system. It is particularly effective in dealing with highly abrasive substances, easily breakable, or composed of extremely fine particles—materials known to cause premature wear in other types of dilute-phase feeding equipment. This pump uniquely combines the benefits of mechanical and pneumatic systems to efficiently handle and convey dry, free-flowing materials (Pulverized Coal, Fly Ash, Cement, Dolomite, Feldspar, Calcined Gypsum, Raw Gypsum, Lime, Talc). It is used for various applications such as Small bags to Silo, Jumbo bags (big bags) to Silo, Loading / unloading of Rail containers, Ships, Trucks etc.

RMX offers a capacity of up to 25 tons per hour.

Features:

- Low inlet hopper height

- Heavy-duty construction

- Ease of Maintenance

- Cost effective

- Ability to handle high capacities

- Minimum maintenance

- Optimum performance

- Maximum efficiency

Silo feeding plays an important role in concrete batching plant for reliable productivity. RMX provides the various silo feeding system for concrete batching plant. This High-volume, Low-pressure system makes it easy to unload 25 Ton the bulker within an hour. It reduces dependability on Compressor mounted bulker.

Features:

- Corrosion resistance

- Longer functional life

- Robust construction

RMX presents its Inclined Screw Conveyor, specifically designed for the powder handling sector. This conveyor is built with durability and reliability at its core, making it an ideal choice for the seamless transfer of powders between various processing stages or locations. Crafted in strict adherence to current industry norms, these conveyors stand out for their robust construction and cost-efficiency, ensuring they meet the specific needs of businesses looking for effective material handling solutions.

RMX offers variable types and capacity screw conveyors to customers based on their requirements and various application up to 100 TPH.

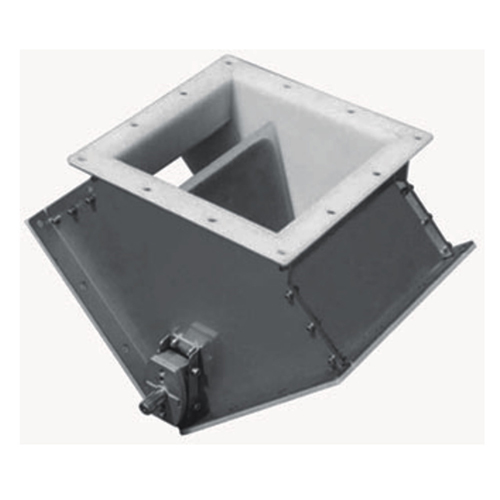

A powder bin activator is a device designed to ensure the smooth discharge of powdery materials from bins or silos. It prevents material blockages by using a vibrating cone mechanism at the bottom of the storage container, promoting a consistent and controlled flow of powder. This device is crucial in industries like food processing, pharmaceuticals, and chemicals, where bulk powder handling is essential.

RMX offers a wide range of bin activators, catering to various sizes and storage capacities.

A dust filter in the powder industry is a device that captures fine particles from the air during powder processing, improving workplace safety and meeting regulatory standards. It passes air through filter media, trapping dust while allowing clean air to flow. These filters are vital for reducing dust-related hazards, including explosions, and are essential for operations like grinding and conveying. Regular maintenance is required to ensure their efficiency. Dust filters are vital in protecting personnel, equipment, and products while minimizing product loss.

RMX offers various types (Venting filter, Ground Mounted Dust filter) & capacities of dust filters catering to RMC vertical as per application needs.

Silo control panels are electronic systems designed to monitor and manage silo operations, including material filling, emptying, and storage conditions like temperature and humidity. They feature automated controls, level indicators, and safety mechanisms to optimize storage, prevent spoilage, and ensure safety. These panels can be integrated with larger facility management systems for efficient, remote operation, maintaining optimal storage conditions and enhancing safety.

RMX offers customized Silo Control Panels designed as per RMC project needs.

Silo-level indicators are devices that measure the material levels in silos, which is crucial for managing inventory and ensuring operational safety. They prevent overfills and shortages by providing real-time level data. These indicators are key to efficient silo management, helping automate refills and maintain optimal storage levels.

RMX offers various types of level indicators, such as rotary paddle, ultrasonic, radar, and capacitance sensors, each suited to different materials and conditions.

Silo-aeration pads are devices installed at the bottom or along the sides of silos to facilitate the flow of bulk powders or granular materials. These pads work by introducing low-pressure air into the silo, helping to break up material clumps and promote consistent flow. Aeration pads are particularly useful in preventing material bridging and rat-holing, common issues in silo storage that can hinder material discharge.

RMX offers aeration pads as accessories for Silos, hoppers, etc., which are easy to install, Self-cleaning design.

Butterfly Valves are a highly preferred choice for sealing silos, hoppers, or bins filled with powders or granules globally. These valves find extensive application across various powder and granular material processing industries for the interception of materials, whether gravity-fed or conveyed pneumatically. Designed to be installed under hoppers, bins, silos, or along screw or other conveyors, as well as in pneumatic conveying ducts, their unique design and the engineering materials employed make them an efficient and cost-effective solution for material flow control.

RMX offers up to 400 mm in size in manual & auto versions. RMX butterfly valves are easy to install, have low maintenance cost, leak-proof design, and are highly Abrasive resistant.

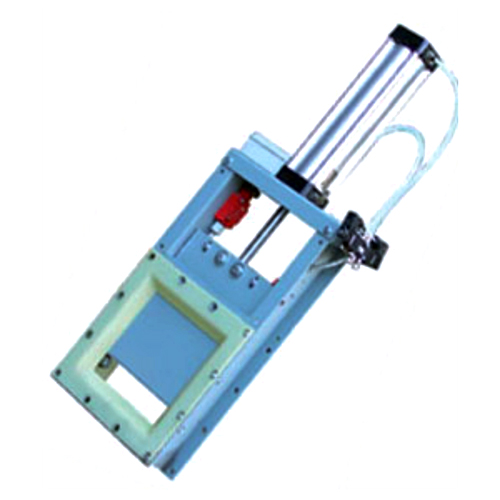

Slide Gate valves by RMX are engineered to perform optimally in demanding situations. They are ideal for controlling abrasive materials like sand, gravel in heavy-duty settings. These valves are tailored to withstand harsh conditions, featuring dual replaceable, abrasion-resistant seals.

In diverse configurations, RMX provides these valves in square and round cross-sections, with sizes up to 400 mm. Customers can choose between manual and automatic versions, each equipped with interchangeable actuators. Renowned for their ease of installation, low maintenance costs, leak-proof construction, and high abrasion resistance, RMX Slide Gate valves offer a reliable solution for material handling.

A silo weighing system accurately measures the weight of materials in silos, which is crucial for inventory management and production control in various industries. It employs load cells under the silo to convert force into electrical signals, displaying the material weight in real-time. This technology aids in preventing overfilling, optimizing material replenishment, and ensuring safety by avoiding overloading. By facilitating accurate inventory tracking and enhancing operational efficiency, silo weighing systems are valuable for cost savings and supply chain optimization.

RMX offers various options of silo weigh systems such as Strain-Gauge, Radar & compression type in a range of 50 Ton to 2000 Ton.

A bulker loading bellow is a telescopic device designed for the efficient, dust-free loading of bulk materials into trucks, ships, or silos. It is commonly used in industries that handle powdery or granular materials, such as cement, grains, fertilizers, and minerals. The bellow extends from a fixed point towards the target container or vessel, channelling the material directly into its destination while minimizing dust emissions and product loss.

RMX offers loading bellow at various application needs to customers.

A diverter valve is essential for efficiently directing powdery or granular materials within a system, offering versatility in processing and distribution across various industries. It operates by diverting flow from one source to multiple destinations, controllable manually or via automated actuators. Key advantages include efficient material handling, operational flexibility, space conservation, and reduced contamination risk.

RMX provides a selection of Diverter Flap Valves in various sizes to meet specific application requirements, reinforcing its commitment to efficient and versatile material management solutions.

The bagging belt conveyor, offered by RMX, is a customized conveyor solution crafted to enhance the bag filling and transportation workflow in industrial environments. Essential for packaging lines handling bulk materials, it ensures seamless movement of bags from the filling phase to sealing, closing, and onward to dispatch, optimizing the bagging process end-to-end.

RMX provides these conveyors in various lengths to suit specific requirements and offers compatibility with additional equipment such as bag stitching, printing, and weighing machines. With features like adjustable speeds and a compact design, RMX’s bagging belt conveyors are engineered for efficiency and integration within diverse packaging operations.

The Centrifugal-High Impact Crusher Mill combines the principles of centrifugal forces and high-impact crushing to achieve efficient size reduction of various materials. This type of mill is particularly effective in breaking down hard, brittle, or fibrous materials into smaller particles through a combination of high-speed rotation and the impact force generated from the materials colliding with each other or against the mill components.

RMX offers up to 500 TPH throughput capacity mill.

The Jumbo Bag Loading & Unloading System, offered by RMX, is engineered to manage large bags effectively, also recognized as bulk bags or FIBCs(Flexible Intermediate Bulk Containers). These systems are crucial in industries where bulk materials like Sand, powders, chemicals, and minerals must be transported or stored in large quantities. Enhancing safety, cutting down on manual labor, and decreasing the risk of product loss or contamination is an essential solution.

RMX’s system accommodates jumbo bags up to 2 tons, aligning with the high-volume needs of the Powder & Sand industries.

RMX’s air classifiers excel in separating particles by size or density, utilizing airflow and gravity for efficient material classification post-grinding or milling. Materials are introduced into a chamber where varying air speeds facilitate the separation process: lighter or finer particles are swept up and away, whereas heavier or coarser particles descend for collection. This technology is adept at managing diverse materials and delivering exact particle size control critical for sectors such as pharmaceuticals and construction, thereby ensuring uniform product quality.

Catering to specific industrial needs, RMX provides air classifiers with up to 40 TPH capacities, specialized for dust materials finer than 75 microns.

Dust Conditioner, also known as DUSTFIX, is recognized for its cost-effectiveness and advanced technological design aimed at the conditioning of industrial dust. Suitable for a wide array of industrial applications, it is ideal for recycling, storing, or disposing of dust. The capability of Dust Conditioner to blend various powder and liquid additives enables the production of dust-free products or the consolidation of powders into more manageable entities. Designed for uninterrupted operation, it features innovative SINT® engineering polymers and boasts a rapid work cycle, ensuring efficiency and longevity.

RMX provides Dust Conditioner models capable of handling up to 80 m³/hr. They are available in various sizes to meet specific application requirements, positioning them as the superior solution for effective dust handling, conditioning, and management.

VCP Pressure Relief Valves serve as critical safety devices for silos, designed to act swiftly in the event of abnormal pressure conditions that could jeopardize the silo’s integrity. These valves are intended to respond immediately to prevent excess or suction pressure from causing structural damage. While the optimal scenario is that a Pressure Relief Valve remains inactive, its effectiveness and reliability are paramount when called upon. RMX provides VCP Pressure Relief Valves, highlighting their essential role in silo safety. These valves are easy to install and lightweight and require minimal maintenance, ensuring long-term protection.

The rotary sand dryer from RMX exemplifies industrial drying efficiency, designed to uniformly dry sand and various other materials through its rotational mechanism. This equipment is adaptable, with settings that can be adjusted to meet the specific drying requirements of different materials. Engineered for high-volume capacity, it meets the demands of large-scale industrial operations. Renowned for its durability and energy-efficient design, the rotary sand dryer minimizes operational costs while delivering consistent, high-quality dry products. Essential for sectors reliant on dry sand, including construction, foundries, and glass manufacturing, RMX’s sand dryers ensure optimal drying performance.

Available with capacities up to 50 TPH, RMX caters to a broad range of fuel preferences, including diesel and coal, accommodating the specific energy resources of the client’s location.

RMX’s bucket elevators are engineered to elevate bulk materials vertically with supreme efficiency and reliability. A bucket elevator is a mechanical device used to vertically transport bulk materials via a series of attached buckets on a belt or chain. Widely utilized across industries like agriculture, mining, and construction, it offers high capacity and efficient vertical conveyance in space-constrained environments. Renowned for their durability and the capability to handle a diverse range of materials, from fine powders to large, bulky items, RMX’s elevators stand out for their energy efficiency. Our bucket elevators come in various lengths and capacities, ensuring an optimal fit for any material transport requirement.

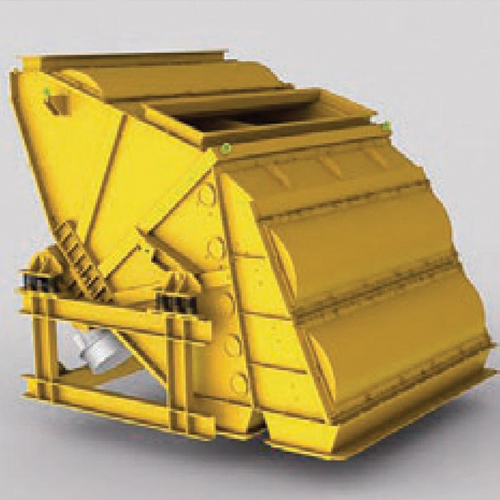

RMX High-performance screens stand at the forefront of precision material separation in sectors such as mining and recycling. Featuring advanced technology, including multi-deck configurations, variable motion, and high-frequency vibration, these screens deliver unmatched efficiency and accuracy. Their effectiveness is rooted in the probability screening principle, allowing for high-capacity sorting of materials of various sizes with remarkable precision.

As essential tools for improving material grading and boosting production efficiency, RMX High-performance screens mark a notable innovation in screening technology. RMX provides these screens with capacities of up to 80 TPH alongside customizable options for the number of decks and screening mesh sizes, catering to a broad range of screening needs.

RMX’s vibrating (Gyro) screens merge precision and efficiency in a compact, circular design. Utilizing gyratory motion for optimal material separation, these screens are versatile, handling a wide range of materials from bulk solids to fine powders in wet and dry conditions. RMX offers up to 30TPH capacity range with a vibratory motor and customizable screening media, ensuring maximum feed rate and efficiency. RMX offers these innovative screening solutions to meet diverse industry needs effectively.

RMX’s Plough Shear (Continuous) Mixers stand at the forefront of mixing technology, combining high-speed operation with a mechanically generated fluid bed for unmatched efficiency in creating uniform mixtures. These mixers, often utilized as Dry Mortar Mixers and Wall Putty Mixers, feature ploughshare or shovel-shaped tools on a central shaft within a cylindrical drum, lifting and swirling materials into a turbulent mixing zone. This action ensures rapid, homogeneous blending before the mix reaches the outlet.

Designed to handle a broad spectrum of materials, RMX mixers are adept with dry bulk solids (powders, granules, short fibers) and combinations of solids with liquids (for processes like moistening and granulating). Their high shear forces are ideal for breaking down agglomerates and achieving a consistent blend across components of varying densities and particle sizes. Available in capacities of up to 6000 liters and constructed from various materials (MS, Abbrax, SS), these mixers can be customized with additional accessories to cater to specific industrial applications.

RMX’s mixers, including their use as Dry Mortar Mixers and Wall Putty Mixers, are particularly valued for processes demanding quick and uniform mixing, showcasing their versatility and efficiency in various mixing tasks.

The RMX Stationary Valve Type Bag Filling Machine specializes in efficiently packaging easy-flowing powdery materials into valve bags, incorporating a precise weighing mechanism for bulk materials ranging from 20 to 50 Kg. Utilizing a filling impeller, the machine directs the material into the valve bag, optimized by coarse and fine flow control for accuracy. Its design allows for the simultaneous weighing of materials during filling, significantly enhancing output per filling station. Accommodating paper bags of just two layers without special valve reinforcement, the machine features a bag resting on a saddle for stability during filling.

RMX offers this machine the capacity to handle 250 bags per hour for bags weighing between 20 kg and 40 kg, streamlining the packaging process with remarkable efficiency and precision.

The RMX Stationary Open Mouth Bag Filling Machine specializes in efficiently packaging easy-flowing powdery materials into open mouth bags, incorporating a precise weighing mechanism for bulk materials ranging from 20 to 50 Kg. Utilizing a filling impeller, the machine directs the material into the open mouth bag, optimized by coarse and fine flow control for accuracy. Its design allows for the simultaneous weighing of materials during filling, significantly enhancing output per filling station. Accommodating paper bags of just two layers without special valve reinforcement, the machine features a bag resting on a saddle for stability during filling.

RMX offers this machine the capacity to handle 200 bags per hour for bags weighing between 20 kg and 40 kg, streamlining the packaging process with remarkable efficiency and precision.

The RMX Bulk Bag Truck Loader is an advanced conveyor system tailored for efficiently loading filled bags into trucks, pivotal for optimizing the packaging line’s final stage. This system ensures fast, safe, and orderly loading, catering to industries that handle bulk materials, including agriculture, food processing, chemicals, and construction materials.

Designed to enhance productivity and safety, the RMX loader supports an impressive capacity of 800-900 bags per hour with a loading height of up to 4 meters, addressing the needs of operations looking for high-efficiency solutions in bag transportation and logistics.